Description

Procuring Custom TN LCD Panels: Optimized for Voltage, Current, Temperature, and Power Displays

In today’s landscape, the integration of LCD liquid crystal displays into instrumentation products is burgeoning. These products span a wide array of fields, from measuring instruments to automotive and power instrumentation. However, the challenge lies in selecting the appropriate LCD screens tailored to these diverse instrumentation categories.

Industrial instruments often operate in harsh environments, demanding stringent reliability from their LCD screens. Conventional LCD screens fail to withstand such rigorous conditions, including extreme temperatures, impact resistance, and protection against dust and water. Therefore, the prudent choice is industrial-grade LCD screens, engineered to meet these exacting standards.

Furthermore, an essential consideration in LCD screen selection is power efficiency. Unlike conventional displays with intricate internal circuits consuming substantial power to drive cathode ray picture tubes, instrument LCD displays boast minimal power consumption. Their energy consumption primarily stems from internal electrodes and driver ICs, significantly reducing power usage compared to traditional displays.

At ShenZhen Techstar Electronics Incorporated Co., Ltd, we specialize in crafting customized LCD displays. As a premier LCD manufacturer in China, we are committed to pioneering research and development, leading to groundbreaking advancements in liquid crystal display technology. Our premium displays find applications across various sectors, including industrial, residential, automotive, medical, and consumer products.

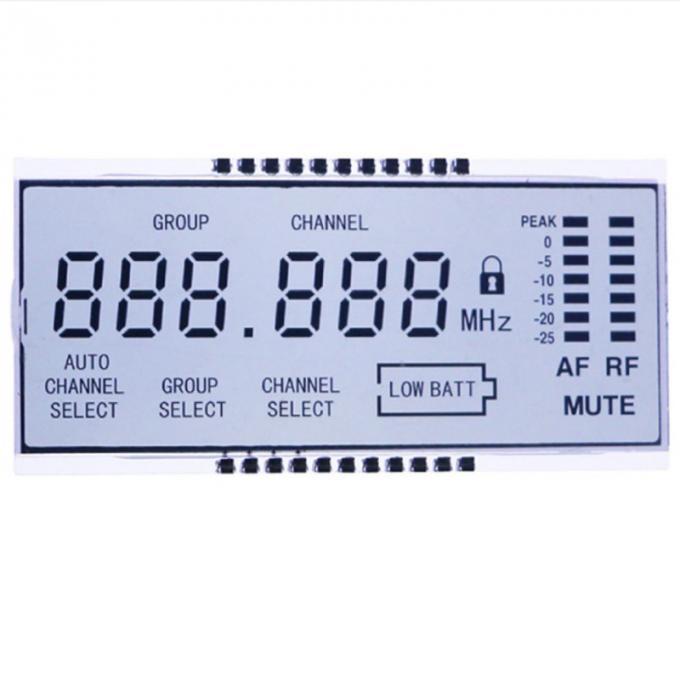

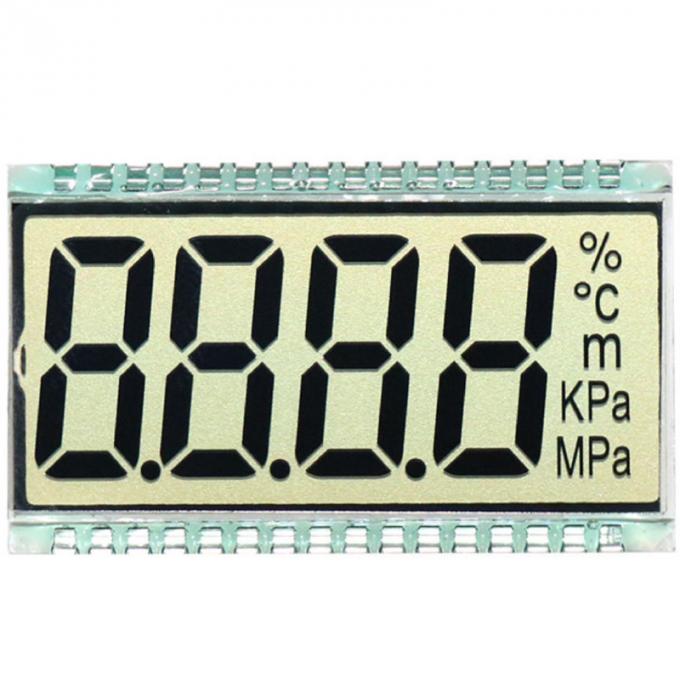

Segment LCD screens offer distinct advantages such as rapid response times, low power consumption, and cost-effectiveness. These attributes make segment LCD screens a preferred choice for many users. However, customization requires meticulous attention to certain parameters before tooling begins. Here are the key considerations outlined by segment code LCD screen manufacturers:

- Size: Determining the dimensions of the viewing area is paramount.

- Backlight: Assess the necessity for backlighting and select the appropriate method (consider bottom or side backlighting, especially for nighttime usage).

- Driver Source: Decide whether to procure drives internally or from an external manufacturer.

- Operating Voltage

- Visual Requirements: Provide display renderings, drawings, or specify desired colors (commonly white on blue, yellow-green, low-black and white on black, etc.).

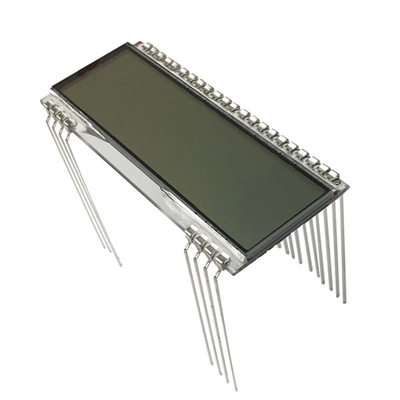

- Connection Interface: Choose between metal pin or zebra connections.

- Display Mode: Select from transmissive, transflective, or reflective (no backlight) modes.

- Viewing Angle: Specify preferred viewing angles (e.g., 6:00, 12:00, 3:00, or 9:00).

By meticulously considering these parameters, you can ensure the seamless integration of custom TN LCD panels tailored to your specific voltage, current, temperature, and power display requirements.

| Product: | Custom Meter LCD |

|---|---|

| Driving Condition: | 1/8 Duty Or Customizable |

| Optics: | 6:00 or cusotmizable |

| Size: | Customizable |

| Operating Temp: | -30°C To +80°C |

| Connection: | Metal Pin Connection |

| Response Time: | 0.1 Ms |

| Display Mode: | Positive / Negative, Transflective/Reflective |

| Operating Voltage: | 3.0 V |

| Display Type: | Transflective / Reflective / Transmissive |

| Backlight: | White / Amber / Blue / Yellow |

| Storage Temp.: | -35°C To +85°C |

| Dot Space: | 0.1 Mm |

| Compliance: | REACH & RoHS Compliant |

Reviews

There are no reviews yet.