Description

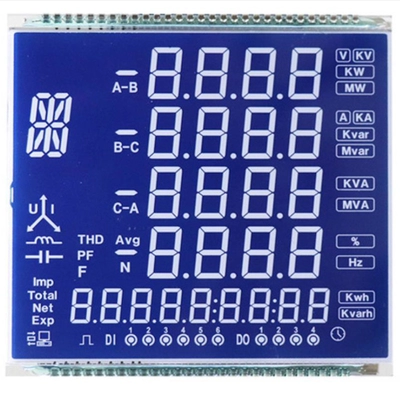

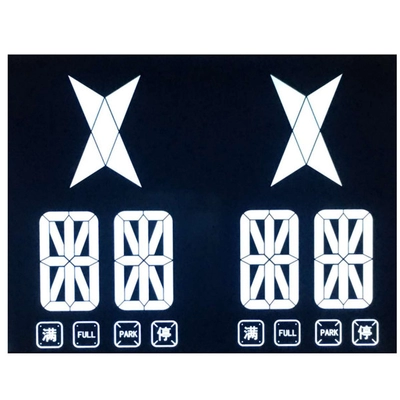

Enhance Your Visual Experience with Our Tailored STN LCD Panel Featuring a Striking STN Blue Mode Against a White Background for Crisp Character Display. Seamlessly Connect with Metal Pins for Optimal Performance.

Fundamentals of STN Technology

The operational concept behind STN technology mirrors that of TN, with a notable difference: while TN manipulates incident light by 90 degrees using liquid crystal molecules in a torsional nematic field effect, STN achieves a rotation of 180~270 degrees. It’s essential to understand that TN LCDs inherently feature only two states—light and dark—without the ability to alter color. However, by integrating a color filter into the traditional monochrome STN liquid crystal display, each pixel within the monochrome display matrix can be subdivided into three sub-pixels (red, green, and blue). Through the harmonization of these primary colors, a full spectrum of colors can be rendered. Furthermore, despite TN LCDs typically having smaller screen sizes, advancements in STN technology effectively compensate for any shortcomings in contrast.

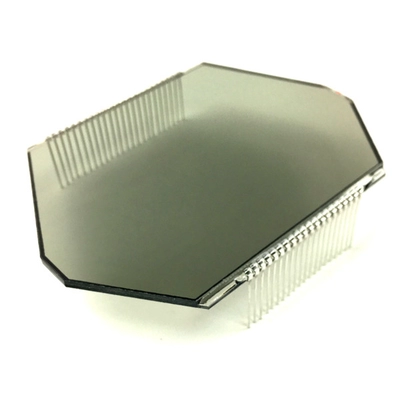

Structure of STN-LCD

Internally, the STN-LCD color screen module comprises an upper LCD screen composed of polarizers, glass, and liquid crystal, while the lower section houses a white LED, a backlight board, the LCD driver IC, and a low dropout regulator (LDO) ensuring stable power for the LCD driver IC. Additionally, it includes two to eight white LEDs and a boost regulator IC controlled by the LED.

Driving Mechanism of the LCD Screen

The simple matrix drive method utilizes vertical and horizontal electrodes, with horizontal voltage controlling the targeted segment and vertical electrodes driving the liquid crystal molecules. In both TN and STN LCDs, the cross drive method of the X and Y axes is employed. However, as the display area increases, the response time of the central electrode may lengthen, potentially slowing overall screen performance. This delay can manifest as screen flickering or lag during rapid transitions, such as in 3D animations. Consequently, early LCD monitors faced size limitations and were less suitable for multimedia consumption.

The active matrix employs a set of electrodes for each element, akin to a DRAM loop, with voltage scanning representing the state of each element. To address the limitations of this approach, later iterations of LCD technology adopted active-matrix addressing. This method employs silicon transistor electrodes fabricated using thin-film technology. By selectively applying voltage to individual display points through transistor matrix electrodes, the liquid crystal molecules are driven to produce desired brightness levels. This approach circumvents the reliance on the electric field effect of liquid crystals, ensuring more precise control over display functionality.

| Product: | Custom STN Blue Mode LCD Display |

|---|---|

| Driving Condition: | 1/8 Duty Or Customizable |

| Optics: | 6:00 |

| Size: | Customizable |

| Operating Temp: | -30°C To +80°C |

| Connection: | Metal Pin Connection |

| Response Time: | 0.1 mS |

| Display Mode: | Negative Transmissive |

| Operating Voltage: | 3.0 V Or Customizable |

| Display Type: | STN |

| Backlight: | White / Amber / Blue / Yellow |

| Storage Temp.: | -35°C To +85°C |

| Dot Space: | 0.1 mS |

| Compliance: | REACH & RoHS Compliant |

Reviews

There are no reviews yet.