With the acceleration of the development of automotive intelligence, the development of on-board displays towards large size, multi-screen, high-definition, interactivity, and multi-form, there are also higher requirements for the performance requirements of the display, including high contrast, low reflectivity, wide viewing angle, high brightness, touch and fast response, etc. In addition, the novel design of the details and structure of the on-board display can also play an unexpected role in improving the competitiveness of the product. Therefore, the All-Black-Effect technology that can create a novel, eye-catching, beautiful and technological in-vehicle display effect will become one of the trends.

1. Definition of All Black Effect

At present, the ink area and the window area of most display screens are usually different colors, and the display screen is in the state of screen off, and the display area and the edge ink area have obvious color difference boundaries, and the visual effect is poor.

With the improvement of consumer aesthetics, everyone’s pursuit of aesthetics is getting higher and higher, so there is a technology that can make the central control screen in the state of screen off, and the color difference between the display area and the edge ink area is difficult to distinguish with the naked eye, so that the on-board display looks integrated with the environment and enhances the high-end sense of the cockpit, which is All Black Effect.

To determine the integrity of the product, the chromaticity difference △E can be used to assist in the measurement. As shown in the figure below, the L value represents the brightness and darkness (black and white), the a value represents the red-green, the b value represents the yellow-blue, and △E=√((L1-L2)²+(a1-a2)²+(b1-b2)²). When △E<2 and the L value of the viewport is less than 28, the integrated black effect is good. When △E≤1, a very good one-piece black effect can be obtained.

2. How to achieve the effect of All Black

The visual perception that “All black” can create makes the appearance of the product more high-end, atmospheric, beautiful and technological, and at the same time creates product differentiation, so as to enhance consumers’ desire to buy. In addition to in-vehicle displays, it is also widely used in smart terminals such as smartphones, smart wearables, and mid-to-high-end touch laptops. So what if the “all black” effect is achieved?

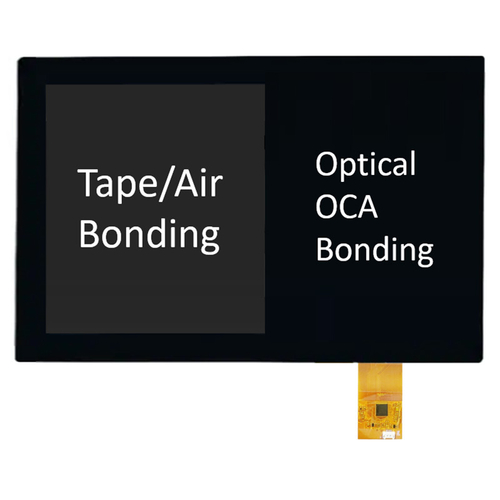

The realization of integrated black has a great relationship with the components of the display screen and the process such as TFT display, polarizer, laminating method, laminating glue, frame ink, coating, etc., which requires the perfect matching of various factors, and the full lamination of the screen helps to achieve the integrated black effect.

In the case that the TFT glass screen has been immutable, there are three ways to implement the “all black” panel.

(1) Silk screen printing method

After the cover plate is CNC, strengthened, silk screen/evaporated black frame, a layer of IR ink transflective printing is made in the window area or key part of the glass cover, and the ink color and transmittance are adjusted to achieve a black effect. It should be noted that the choice of semi-translucent black ink should be the same color as the border color, and the color should be close. Too dark and too light, it will cause color difference segment layer. Control of transmittance: Depending on the brightness of the LED lamp and the environment in which it is used, the transmittance varies from 1% to 50%. At present, the two most used are 15±5% and 20±5%.

(2) Coating

Different from the silk screen printing method, the technology independently developed by SAEF Technology to achieve “all black” is to directly coat a layer of inorganic film on the glass cover plate through magnetron sputtering and optical principles, and adjust the reflection, transmission and color difference of the window area of the film layer, so that the color of the touch screen window and the screen printing frame are consistent. The transmittance can reach 80%, and the reflectivity is less than 2%. The difference between the AR coating and the non-display of Changxin Technology.

(3) The cover plate is made of translucent material

In addition to the two post-processing processes of silk screen printing and coating, semi-transparent material can also be directly used to achieve the effect of “all black”, and the material can be plastic or glass. The integrated black processing of plastic materials is usually to add toner to the resin material, and to achieve the effect of “integrated black” by adjusting the amount of toner added to the material; Glass can be produced with added color or dyed. The glass material needs to rely on the original glass factory for blending or using a semi-permeable film. The processing method of directly using translucent material can achieve a good “one-piece black” visual effect, and the surface permeability of the cover plate is consistent.

(4) Using smoky color OCA/OCR

From the structure of the display screen, the effect of integrated black is the color consistency of the light after passing through the cover, TP layer, LCM layer, and optical glue of full lamination. Therefore, in addition to the cover, TP, and LCM liquid crystal layers, the color of the optical glue part can also be adjusted to reduce the color difference between the display part and the edge part.

Summary:

In general, the “all black” effect can greatly improve the static beauty of the display, which makes the surface of the product look more beautiful, more luxurious, and more technological, and improves the quality of the display product from the appearance, bringing consumers a better experience. However, there are some points to be noted in production:

1. One black will involve different angles, so it is necessary for customers to confirm the Δ value at different angles.

2. The integrated black has a great relationship with the components of the display screen and the process methods such as TFT display, polarizer, laminating method, laminating glue, frame ink, coating, etc., so it is necessary for downstream customers to plan as a whole to achieve the perfect match of various factors.

Leave a comment