With the development of technology, more and more of our electronic devices, especially the development of touch screens, are getting higher and higher for the optical materials for the structure of optical bonding, which are required to have colorless transparency, light transmittance of more than 98%, good bonding strength, can be cured at room temperature or medium temperature, and have the characteristics of small curing shrinkage, this adhesive is called optical adhesive. Optical adhesives made of different materials such as silicone, acrylic resin, unsaturated polyester, polyurethane, epoxy resin, etc.

1. What is OCA

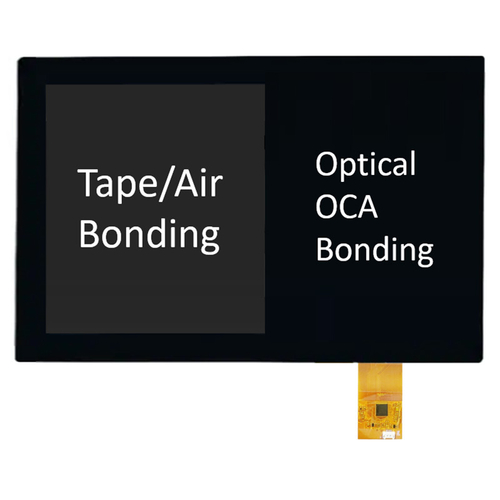

OCA (Optically Clear Adhesive) is a double-sided adhesive tape without matrix material obtained by making optical acrylic glue into no substrate material, and then laminating a layer of release film on the upper and lower layers.

2. Advantages of OCA

High cleanliness, high light transmittance, low haze; The thickness of the adhesive layer is uniform and the flatness is high; High adhesion and high bonding strength after lamination; Soft to soft, soft to hard, hard to hard can be fitted, and the fit material has a wide applicability.

3. OCA manufacturer

3M and TESA are the main ones, and the 3M production capacity is mainly occupied by traditional LCD manufacturers for a long time, and basically occupies the highest-end market; Mitsubishi and Nitto Denko from Japan, South Korea is LG Chemical and SKC from South Korea.

4. What is OCR

OCR (Optical Clear Resin) is a kind of optical glue, because the glue is in a liquid state, it is also known as liquid optical glue, optical water glue or LOCA. After curing, the glue is colorless and transparent, with a light transmittance of more than 98%, and has the characteristics of small curing shrinkage and yellowing resistance. In the field of optical lamination, compared with traditional OCA tapes, OCR has unique advantages in large size, curved surfaces, harsh environments and other fields.

5. Advantages of OCR/LOCA

1) Strong applicability, one glue can correspond to a variety of laminating products;

2) Liquid glue has strong fluidity, is not sensitive to ink thickness, and has good gap filling;

3) It is suitable for large-size lamination, and there is no restriction on the size of the laminating product;

4) It is suitable for surface lamination or complex structure lamination;

5) High lamination yield and good rework performance;

6) Chemical bonding, the bonding is less affected by temperature, and the bonding stability is strong.

6. OCR/LOCA production companies are: Wacker, Henkel, Momentive, DuPont;

SAEF Technology is committed to providing complete solutions for functional materials for the smart and touch industries, and has developed high-sensitivity silicone OCR products for touch screens that are used in the optical lamination process of display components such as cover glass, touch sensors and LCD modules. The combination of silicone OCR and A/R glass perfectly solves the problem of light loss in the air layer between the touch screen and the display panel, which can increase the contrast by 400% in sunlight and improve the visibility of the touch screen inside and outside. Silicone OCR for high-sensitivity touch panels can be used for a long time in the range of -50-200°C, which improves the reliable performance of the display and thus extends the life of the display product. Compared with frame-mounted components, silicone OCR/LOCA for high-sensitivity touch screens can also reduce the impact of external impacts, improve impact resistance and bending strength, and increase the reliability of touch screens. Liquid silicone OCR enables a wide range of product adhesion thicknesses, better fills gaps between inks and coatings, and enables thinner designs.

Leave a comment