Quality Management

-

1. Quality policy

- 2. EHS policy

- 3. Measures adopted

- Provide sound quality and deliver goods on time;

- To satisfy requirements of customers with continuous improvement

- To observe laws and regulations and to prevent and control pollution;

- To try to reduce emission and conserve and make full use of resources;

- To improve environmental protection awareness and continuously improve the environment;

- It will make transparent its quality policy and improve employees’ awareness on quality via training and education;

- By implementing ‘5S’ management, it will make office and production spot tidy and orderly and employees well-trained;

- It will make sure that the ISO9001 quality guarantee system cover all rounds affecting qualities of products and services before incorporating them to regulated and procedural management and control;

- Under the premise that quality is guaranteed, it will reduce production costs including reduction of costs of raw materials and improvement of production and managerial efficiency.

1. Quality Engineering

- Provide sound quality and deliver goods on time;

- To satisfy requirements of customers with continuous improvement

2. EHS policy

- To observe laws and regulations and to prevent and control pollution;

- To try to reduce emission and conserve and make full use of resources;

- To improve environmental protection awareness and continuously

3. Measures adopted

- It will make transparent its quality policy and improve employees’ awareness on quality via training and education;By implementing ‘5S’ management, it will make office and production spot tidy and orderly and employees well-trained;

- It will make sure that the ISO9001 quality guarantee system cover all rounds affecting qualities of products and services before incorporating them to regulated and procedural management and control;

- Under the premise that quality is guaranteed, it will reduce production costs including reduction of costs of raw materials and improvement of production and managerial efficiency.

QA Organization

Quality Certification

- Certification of quality system

- Research of quality management

- Application of SPC techniques

Quality Engineering

- Evaluation on supplier

- Appraisement on measurement items and methodology

- Appraisement on quality plan

- TQM management

- Quality analysis

- Organization on measuring and calibration

Quality Audit Assurance

- Quality standardization

- Review and management of MI & customer documentation

- Participation in Contract review

- Customer servies

- ISO certification

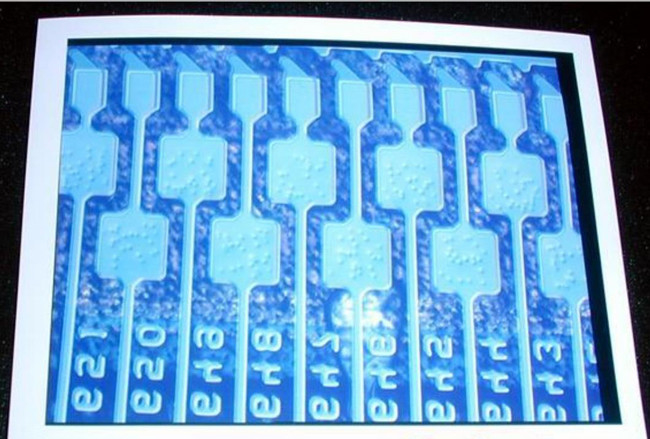

TFT LCD Module QC Process

The LCM is actually the “back-end” production process of liquid crystal displays. it has three steps:

Step 1: The LCD liquid crystal finished panel (Cell), anisotropic conductive adhesive (ACF), driver IC, flexible circuit board (FPC) and the PCB circuit board are pressed together by a machine

Step 2: Assemble the finished product together with the backlight board, light source and iron frame;

Step 3: aging treatment.

1. Visual Testing after COG/TAB

3. Check whether the glass substrate conforms to the specifications, including: glass thickness, size, flatness and other projects. In addition, the glass must be inspected for scratches, shadows or any changes in the surface.

4. Check the unevenness (Mura) on the front and back of the color filter with the poor color rendering of the sodium lamp.

COMPANY DETAILS

MAIN MARKET

NORTH AMERICA

WESTERN EUROPE

EASTERN EUROPE

SOUTHEAST ASIA

BUSINESS TYPE

MANUFACTURER

BUSINESS TYPE

BRANDS : SAEF

NO. OF EMPLOYEES : 400~500

ANNUAL SALES : 40000000-50000000

YEAR ESTABLISHED : 2007

EXPORT P.C : 80% – 90%